The benefits of tactile studs with inserts

Full metal tactile studs are vital in conveying key tactile messages underfoot for the visually impaired and are a vital part of how they commute and navigate our streets and city centres. However, there are alternatives to the traditional formula that can improve this experience for both the visually impaired community and the general population at large.

What is the alternative to full metal tactile studs?

Tactile studs with inserts are a valuable alternative to their full metal counterparts. They’re structured in the same way as a traditional tactile stud but with a recessed cut out in the surface of the stud, in which an insert can be placed.

What inserts are available?

There are many inserts available; these include but are not limited to:

TPU – Thermoplastic Polyurethane

TPU is a plastic that can have many features depending on its composition. The TPU used in tactile stud inserts is generally semi-elastic and has grippy anti-slip properties. Read more about TPU here.

The benefits of TPU are:

- High resistance to abrasion

- Fantastic low-temperature performance

- High elasticity

- Chemical contamination resistant – i.e., oil and grease

- Can be manufactured to good grip ratings (aka R Rating)

PVC – Polyvinyl Chloride

PVC is another type of thermoplastic that also features varying qualities depending on its composition. PVC used in tactile stud inserts tends to share the same features as PVC or vinyl flooring.

The benefits of PVC are:

- Great chemical resistance

- Resistance to fading due to sunlight

- Won’t oxidise from continuous contact with water

- Can be manufactured to good grip ratings (aka R Rating)

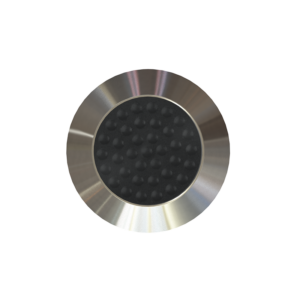

Anti-Slip Tape

Anti-slip tape is usually found as a roll of tape with a textured surface made from an abrasive grit coating. This same tape is used in the inserts of some tactile studs.

The benefits of anti-slip tape are:

- Fantastic grip ratings are available

- Easy and cheap to replace

- Decent weatherproof performance

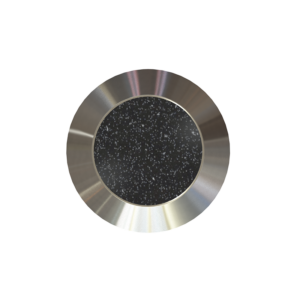

Carborundum

Carborundum or silicon carbide is manufactured for use as an abrasive due to its hard nature and grainy texture. Carborundum is most found as the material used for brake pads, car clutches, and ceramic plates for bulletproof vests.

The benefits of carborundum are:

- Very hard-wearing

- Great grip profiles

- Weather resistant

- Contamination resistant

What are the benefits of using tactile studs with inserts?

The benefits of using tactile studs with inserts over more traditional full metal studs are:

Increased visibility and matching aesthetic

In the case of TPU, PVC and anti-slip tape, they come in a wide selection of colours, including commonly used RAL colours. This is great because it enables the studs to be offset from the pavement surrounding them, increasing their visibility for the visually impaired as well as the general public. For use in an area where the concern is more focused on grip, the colour can be customised to suit the aesthetics of the environment they’re placed in.

Increased grip levels

Another advantage to using inserts is that they can offer grip levels over and above that of a standard full metal stud. There are much higher R-ratings available for inserts than there are for the full metal studs of any pattern. This is primarily because different materials can be harnessed in their construction. Increased grip levels make them great for areas that are prone to contamination with oil and grease and are ideal for locations with high rainfall. Pedestrians can walk with confidence without fear of losing their footing.

What are the downsides to tactile studs with inserts?

There are trade-offs to these fantastic benefits in the form of increased maintenance. In the case of anti-slip tape inserts, over time they can come unseated or wear out and may need to be replaced. Luckily this isn’t a major task as the old grip tape can be removed and any preferred brand and colour can be cut to size and stuck in its place. With TPU, PVC and Carborundum this is much less likely due to their more rigid nature as materials. In the unlikely event the inserts were to come unseated it’s tricker to replace them and may require repurchasing.