Screw-hole tactile studs and strips

Screw-hole tactile studs and strips are more disruptive to surfaces than their self-adhesive counterparts. However, they are much longer lasting, particularly when installed on surfaces that self-adhesives aren’t suitable for, such as wood. Screw-hole tactiles can be described as a more short-to-medium term solution.

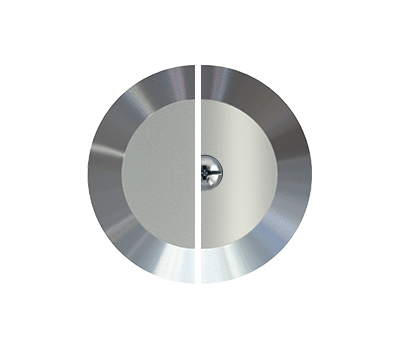

They’re installed by drilling into the underlying substrate to create a pilot hole, inserting a Rawl plug, before screwing down the tactile stud or strip.

Screw-hole studs can be installed into most surfaces e.g., wood, cement, stone, vinyl, ceramic

To remove screw-hole studs and strips they simply require unscrewing from the surface that they’re fixed into. The hole can then be filled with a wood, cement, plaster, or other appropriate filler. Thes studs and strips can then be reused in other projects or locations.