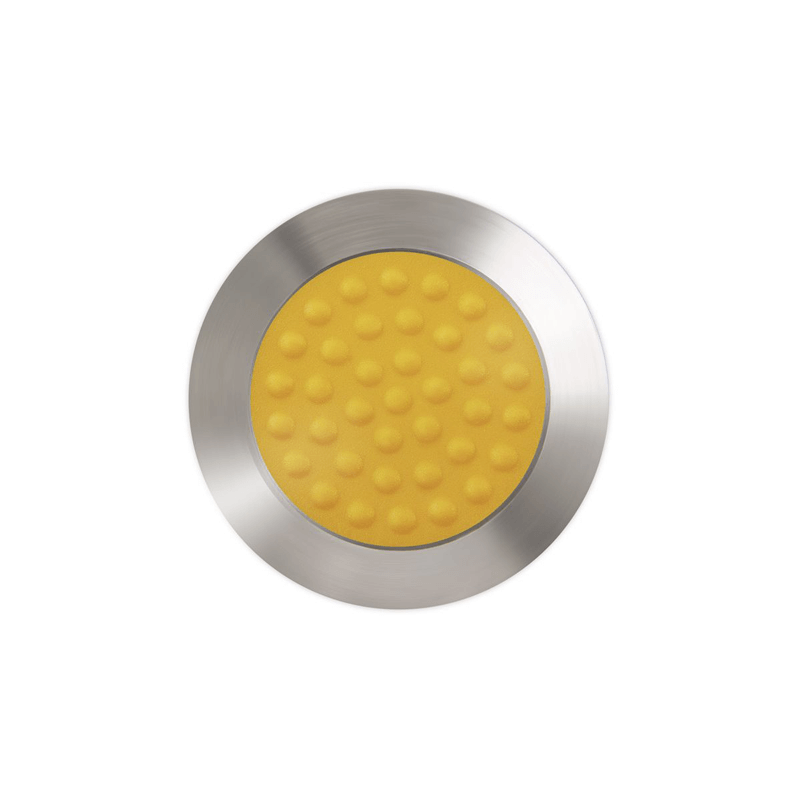

Self-adhesion works incredibly well with surfaces like ceramic tiles and artificial stone, like the kinds of surfaces you’d find in a shopping centre. It’s a great solution for the likes of shopping centres, cinemas, hotel foyers, and anywhere with a similar type of flooring, as it introduces the least amount of disruption and can be removed later should the layout need changing. It’s not quite as big of a commitment as drilling into the floor but still provides that longevity.

They can also be applied to wood and concrete but in this scenario fixing pins may be preferable with screw holes being ideal for wooden surfaces. Read more about applying tactile studs and strips to wooden surfaces here.

Longevity

When applied correctly on a prepared surface, self-adhesive tactile studs and strips will endure the test of time. Especially indoors, as they’re not going to come up against harsh weather conditions or vehicular traffic like they would in an outdoor setting. Again, that’s not to say self-adhesion is a sub-optimal choice for outdoor use, but when there’s an option to drill and resin your studs and strips, it’s best to take that route for peace of mind.

Type of self-adhesive

Our self-adhesive tactile studs and strips use 3M VHB 5925 as standard. We chose this self-adhesive because it holds up the best against heavy traffic and severe weather in the event of outdoor installation. It’s also highly effective without priming the surface, so it’s an extra guarantee of a good bond.

Other types of self-adhesive include:

- Gerband 941 – A cost-effective alternative that works well on smooth non-porous surfaces

- 3M 93020LE – Similar to Gerband 941 but the surface will require priming, and it works reasonably well on concrete

- Bimeks ACR064BS – A cheaper alternative to 3M VHB 5925,it has many of the same qualities to a slightly lesser degree